-Packaging Solutions-

Follow 「Shinelee」 to explore Packaging Solutions

「Shinelee」 offers comprehensive Packaging Solutions tailored to businesses of all sizes, from startups to global enterprises. Specializing in carton packaging, we provide custom designs that meet the specific needs of each client. Our solutions focus on sustainability, utilizing eco-friendly materials, and innovative design to enhance both functionality and brand appeal.

Whether you’re looking for sturdy packaging for e-commerce, premium luxury cartons, or efficient shipping solutions, 「Shinelee」 delivers Packaging Solutions that not only protects your product but also elevates your brand.

What are Packaging Solutions

Packaging solutions refer to a range of services and products designed to protect, store, and present goods during transportation, storage, and retail. These solutions encompass various types of packaging materials and designs tailored to meet the specific needs of different industries and products. Packaging solutions can include:

Protective Packaging

Ensures that products are safe from damage during shipping or handling, using materials like corrugated boxes, bubble wrap, or foam inserts.

Custom Packaging

Tailored packaging designed to fit the exact dimensions and branding needs of a product, such as printed cartons or branded boxes.

Sustainable Packaging

Packaging made from eco-friendly, recyclable, or biodegradable materials, aimed at reducing environmental impact.

Functional Packaging

Packaging designed with additional features, such as resealable closures, easy-to-open tabs, or smart technologies like QR codes or tracking systems.

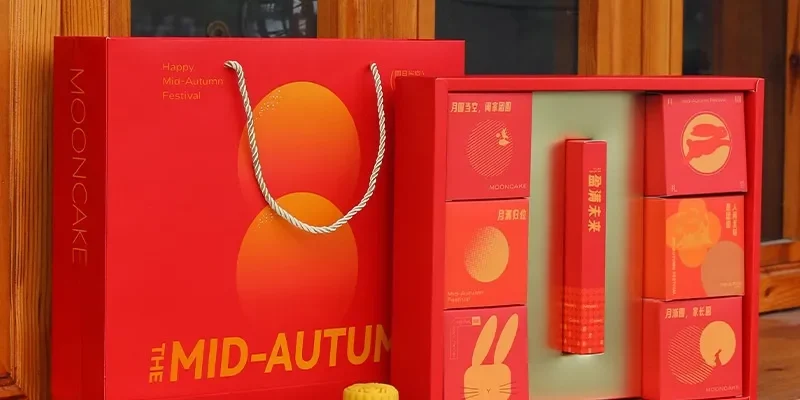

Luxury and Premium Packaging

High-end packaging with premium finishes like embossing, foil stamping, or glossy coatings, enhancing the perceived value of a product.

Our commonly used carton packaging

Carton packaging is widely used across various industries due to its versatility, durability, and eco-friendliness. Here are some industries that commonly use carton packaging:

Our best products

Showing 9–16 of 186 results

-

【 Advent Calendar 】 – Advent Calendar 24pcs Decoration Tree box

Read more -

【 Advent Calendar 】 – advent calendar 24pcs House Shape

Read more -

【 Advent Calendar 】 – advent calendar 24pcs House Shape

Read more -

【 Advent Calendar 】 – Advent Calendar 24pcs Jewellery box

Read more -

【 Advent Calendar 】 – Advent Calendar 24pcs Skin Care box

Read more -

【 Advent Calendar 】 – Advent Calendar 24pcs Tea Bag box

Read more -

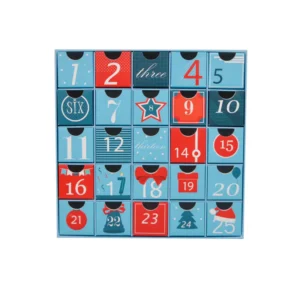

【 Advent Calendar 】 – advent calendar 25pcs Beauty box

Read more -

【 Advent Calendar 】 – Advent Calendar 25pcs Drawer box

Read more

Get Free Sample

Packaging Solutions Process

The packaging solutions process typically involves several key steps to ensure that the final packaging meets the product’s needs, brand requirements, and market expectations. Here is an outline of the process:

Consultation and Needs Assessment

The process begins with understanding the client’s product, target market, and specific packaging requirements. Factors such as product size, weight, fragility, branding, and sustainability goals are considered. This step involves gathering information to define the best packaging solution.

Design and Concept Development

Based on the client’s needs, packaging designers create initial concepts and designs. This includes structural design (size, shape, and material) and visual design (graphics, logos, colors). The goal is to ensure the packaging is both functional and visually appealing.

Material Selection

The appropriate materials are chosen based on the product’s requirements. For example, corrugated cardboard may be selected for heavy items, while folding cartons could be used for lighter goods. Sustainable and recyclable materials are often preferred to reduce environmental impact.

Prototyping and Sampling

A prototype or sample of the packaging is produced for evaluation. This allows the client to test the fit, functionality, and appearance of the packaging before moving to full production. Adjustments can be made at this stage to optimize the design.

Testing and Quality Assurance

Packaging is tested to ensure it meets the necessary durability, safety, and regulatory standards. This can include testing for strength, impact resistance, and environmental sustainability. For products being shipped, transit tests may be conducted to ensure the packaging protects the product during handling and transportation.

Production and Printing

Once the design is finalized, the packaging moves into full-scale production. High-quality printing techniques are used for branding, labels, and product information. Materials are cut, assembled, and printed according to the specifications set during the design phase.

Delivery and Distribution

After production, the packaging is shipped to the client or their distribution centers. Efficient logistics are key to ensuring timely delivery, especially for large orders or time-sensitive products.

Feedback and Iteration

Post-production feedback is gathered from the client to assess the performance of the packaging. Any necessary adjustments or improvements are made for future production runs, ensuring continuous improvement in packaging quality and effectiveness.

The packaging solutions process is a collaborative effort that ensures the final product is functional, visually appealing, and aligned with the brand’s goals and customer expectations.

Things to note about Packaging Solutions

When considering packaging solutions for your products, it’s essential to pay attention to several key factors to ensure you make the best choice. Here are important things to note:

Product Requirements

- Understand your product’s size, weight, fragility, and shelf life. The packaging must provide adequate protection and ensure the product stays intact during shipping, storage, and display. Fragile items may need additional padding, while perishable goods may require specialized materials for temperature control.

Material Selection

- Choose the right materials based on durability, cost, and sustainability. Options range from cardboard, plastic, and glass to eco-friendly alternatives like recycled paper or biodegradable materials. Ensure that the material aligns with your brand’s sustainability goals and is appropriate for your product type.

Cost Considerations

- Balance the cost of packaging with your overall budget. While premium packaging may enhance brand perception, it should be cost-effective. Consider bulk orders to reduce per-unit costs, but ensure that quality is not compromised for savings.

Compliance and Legal Requirements

- Be aware of any industry-specific regulations your packaging must meet, such as food safety, labeling, or hazardous material requirements. Ensuring compliance with local and international laws is critical to avoid legal issues.

Supply Chain and Lead Time

- Factor in the time it takes to design, produce, and deliver packaging. Plan ahead to meet deadlines and ensure that your packaging supplier can meet your production timelines, especially for high-volume or seasonal orders.

Branding and Design

- Packaging is a major branding tool, so consider custom designs that reflect your brand’s identity. High-quality printing, color schemes, logos, and finishes like embossing or foil stamping can enhance brand visibility and appeal to your target audience.

Sustainability

- As consumer demand for eco-friendly products grows, consider sustainable packaging options that minimize environmental impact. Using recyclable or compostable materials and reducing excess packaging can improve your brand’s image and appeal to environmentally conscious consumers.

Functionality and User Experience

- Ensure that the packaging is functional and easy to use. This includes features like resealable closures, tamper-evident seals, or easy-to-open designs. Packaging should be practical for consumers while still maintaining its protective function.

Testing and Prototyping

- Before committing to full production, request samples or prototypes to test the fit, durability, and overall look of the packaging. This step allows for adjustments and ensures that the final product meets your expectations.

E-commerce Considerations

- If your product is sold online, ensure the packaging is suitable for e-commerce. It should be durable enough to withstand shipping and handling while offering a good unboxing experience. Proper e-commerce packaging also reduces the risk of returns due to damage.

By considering these factors, you can ensure that your packaging solutions are effective, functional, and aligned with your brand’s goals and values.

Importance of Packaging Solutions

Packaging solutions play a crucial role in product success for several reasons:

Product Protection

- Packaging shields products from damage during shipping, handling, and storage. Proper packaging ensures that goods reach customers in pristine condition, minimizing returns and complaints.

Brand Identity and Recognition

- ackaging serves as a key branding tool. Custom designs, logos, and colors create a strong visual identity, helping consumers recognize and remember a brand. Eye-catching packaging also makes products stand out on shelves or online platforms.

Customer Experience

- Good packaging enhances the customer experience by making products easy to open, use, and store. Packaging that is aesthetically pleasing, functional, and well-designed can leave a lasting positive impression on consumers.

Sustainability

- Eco-friendly packaging solutions reduce environmental impact, which is increasingly important to both consumers and businesses. Sustainable packaging aligns with corporate social responsibility goals and can enhance brand reputation.

Compliance and Safety

- Packaging solutions ensure that products meet legal and regulatory standards, especially in industries like food, pharmaceuticals, and electronics. This includes safety labeling, tamper-evident seals, and compliance with packaging regulations.

Marketing and Promotion

- Packaging can be a powerful marketing tool, communicating product information, features, and benefits. It also serves as an opportunity for promotions, seasonal campaigns, or limited-edition designs that drive sales.

Cost Efficiency

- Well-designed packaging optimizes material usage and reduces shipping costs by minimizing weight and volume. Efficient packaging solutions can also lower overall production costs while maintaining product safety and quality.

Product Differentiation

- Unique and innovative packaging solutions help differentiate a product from competitors. A distinctive design or packaging feature can attract more customers and give the product a competitive edge in the marketplace.

In summary, effective packaging solutions are essential for protecting products, enhancing brand identity, improving customer experience, ensuring compliance, and driving marketing success, while also aligning with sustainability goals.

Packaging Solutions - FAQ

Packaging solutions are crucial for ensuring product protection during transit, enhancing brand identity, improving customer experience, and meeting regulatory requirements. They help in safeguarding products, making them visually appealing, and ensuring they comply with legal standards.

Common materials used in packaging solutions include:

- Cardboard: For shipping and retail packaging.

- Plastic: For durability and flexibility.

- Glass: For a premium presentation and product preservation.

- Eco-friendly options: Recycled, biodegradable, and compostable materials.

When selecting packaging solutions, consider the product’s size, weight, and fragility, as well as your budget and sustainability goals. Choose materials that offer adequate protection and align with your environmental and branding objectives.

Custom packaging in packaging solutions involves creating packaging specifically designed for your product and brand. This includes custom sizes, shapes, graphics, and finishes to enhance brand recognition and meet functional needs.

To ensure environmentally friendly packaging solutions, opt for materials that are recyclable, biodegradable, or made from recycled content. Minimize excess packaging and look for certifications that indicate sustainable practices.